Boost Your System’s Performance Using Membrane Switch for Consistent Functionality

Boost Your System’s Performance Using Membrane Switch for Consistent Functionality

Blog Article

Discover the Versatile Utilizes of Membrane Switch Over in Modern Electronics

In the realm of modern-day electronic devices, the application of membrane layer switches is remarkably substantial, extending from streamlined customer devices to essential clinical devices. As markets proceed to advance, the assimilation of membrane buttons in equipment style is critical, encouraging not only to satisfy yet surpass the strenuous needs of both capability and visual allure.

Exploring the Role of Membrane Layer Switches Over in Consumer Electronic Devices

Why are membrane switches over so common in customer electronic devices? Membrane switches are affordable to produce, making them an eye-catching option for high-volume production common in customer electronic devices.

Moreover, these buttons are recognized for their sturdiness and low maintenance. From microwave stoves to remote controls, membrane switches supply a functional, easy to use user interface that sustains the dynamic nature of customer electronic devices.

Membrane Switches in Medical Gadgets: Enhancing Interface

Membrane buttons also play a considerable duty in the world of medical gadgets, where they enhance individual interfaces with their unique advantages. The smooth, covered surface of membrane changes permits for easy disinfection, minimizing the threat of contamination and spread of pathogens.

Membrane layer buttons additionally add to the resilience of clinical tools. Their resistance to pollutants and liquids ensures that vital tools stays operational in different medical setups, including surgeries where direct exposure to fluids is common. This toughness, coupled with responsive comments and low-profile style, makes membrane layer switches an integral component in boosting the efficiency and security of medical device interfaces.

The Impact of Membrane Turns On Industrial Equipment Design

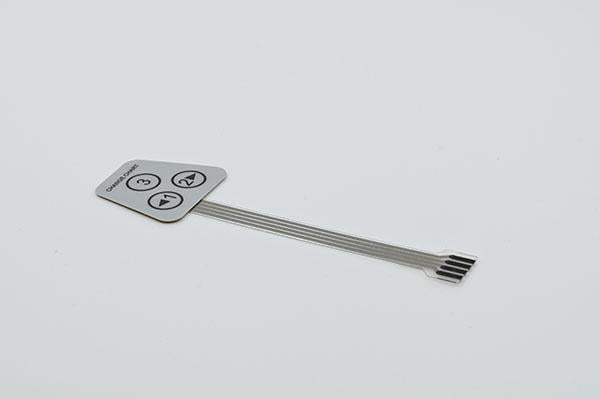

In the realm of commercial devices design, the incorporation of membrane buttons has marked a substantial advancement. The slim profile of membrane changes allows for more portable machine designs, while their resistance to chemical, dirt, and water impurities makes them suitable for industrial settings.

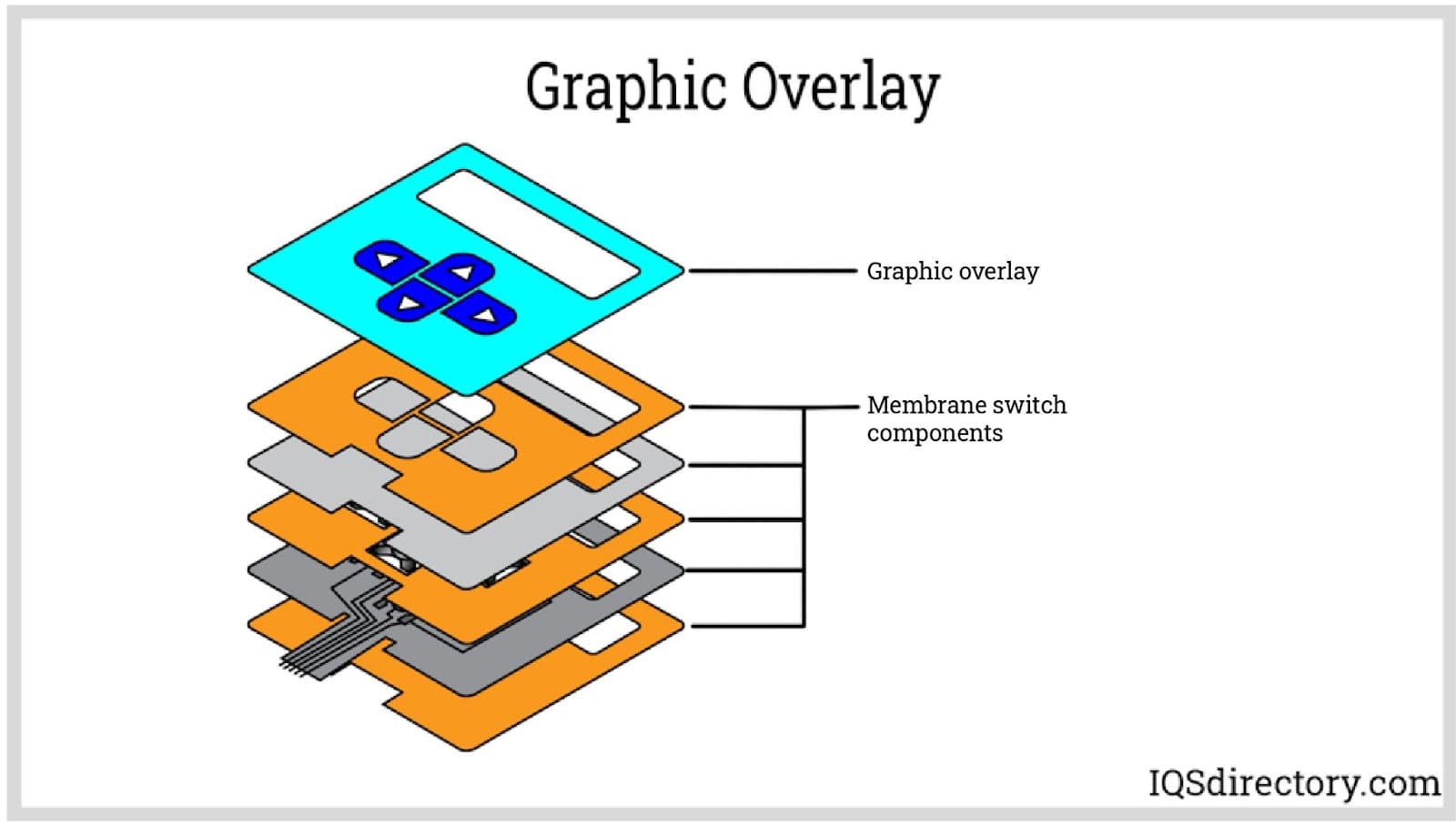

Furthermore, the webpage customizability of membrane layer changes enables developers to integrate particular tactile responses and graphical overlays that improve the customer experience and increase performance. This assimilation supports operators in achieving precision control over complicated machinery. The total you could try here effect is a substantial improvement in the performance, dependability, and user-friendliness of industrial devices, straightening with the increasing needs for technological development and functional effectiveness in modern-day industries.

Verdict

Membrane layer switches have actually revolutionized modern electronic devices, providing sleek, resilient, and personalized interfaces across various industries. This innovation not only fulfills the requiring problems of different areas however additionally substantially improves individual experience, making membrane layer switches over a keystone of modern digital layout.

In the world of contemporary electronic devices, the application of membrane buttons is incredibly substantial, covering from sleek customer gizmos to essential medical gadgets.Why are membrane layer changes so widespread in consumer electronic devices? Membrane layer buttons are cost-efficient to manufacture, making them an appealing alternative for high-volume manufacturing typical in consumer electronic devices. From microwave ovens to remote controls, membrane layer buttons give a sensible, easy to use user interface that sustains the dynamic nature of consumer electronic devices.

Report this page